- Home

- Solutions

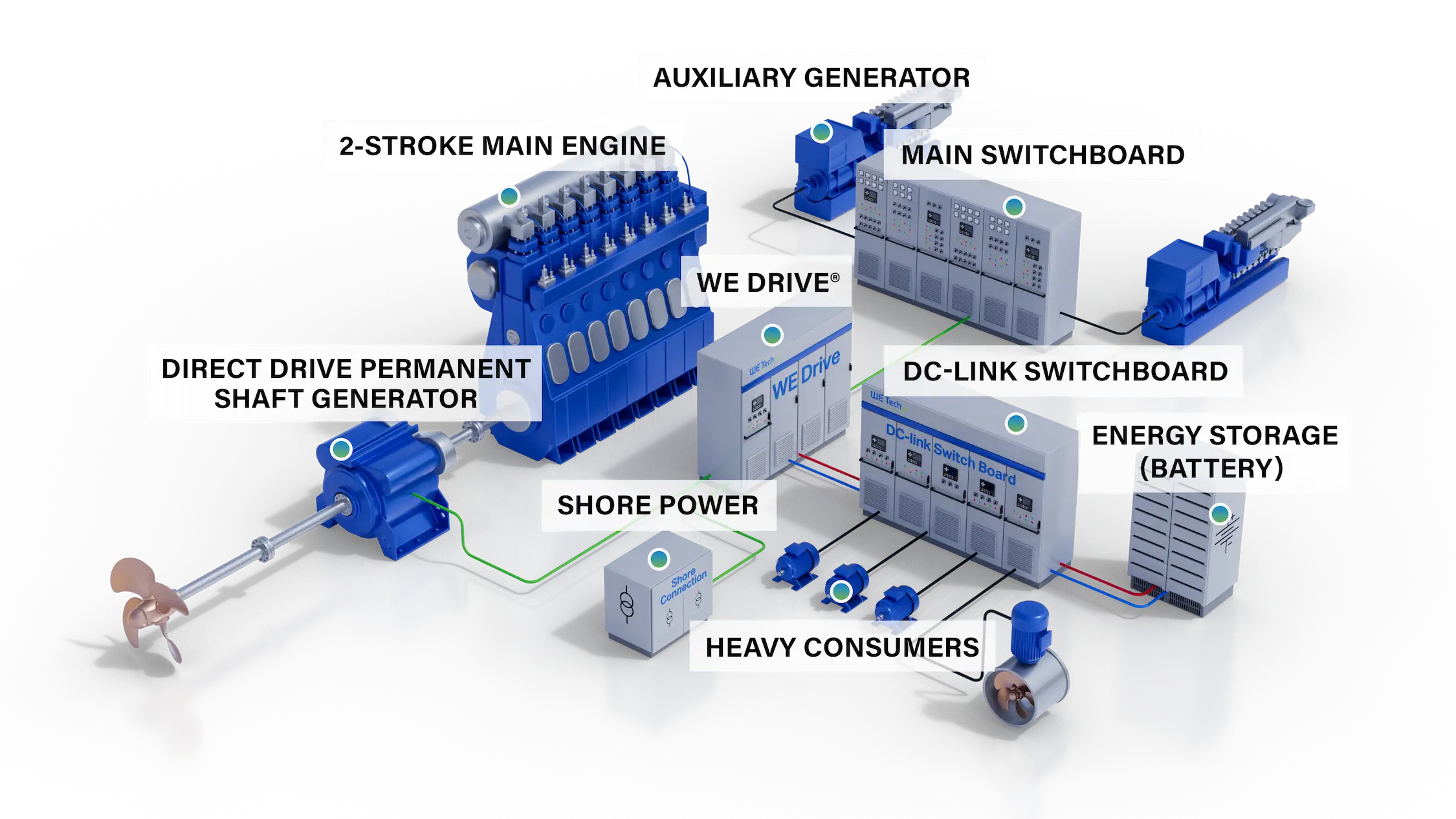

Solution One

PTO Shaft Generator

Economical Ship Operations

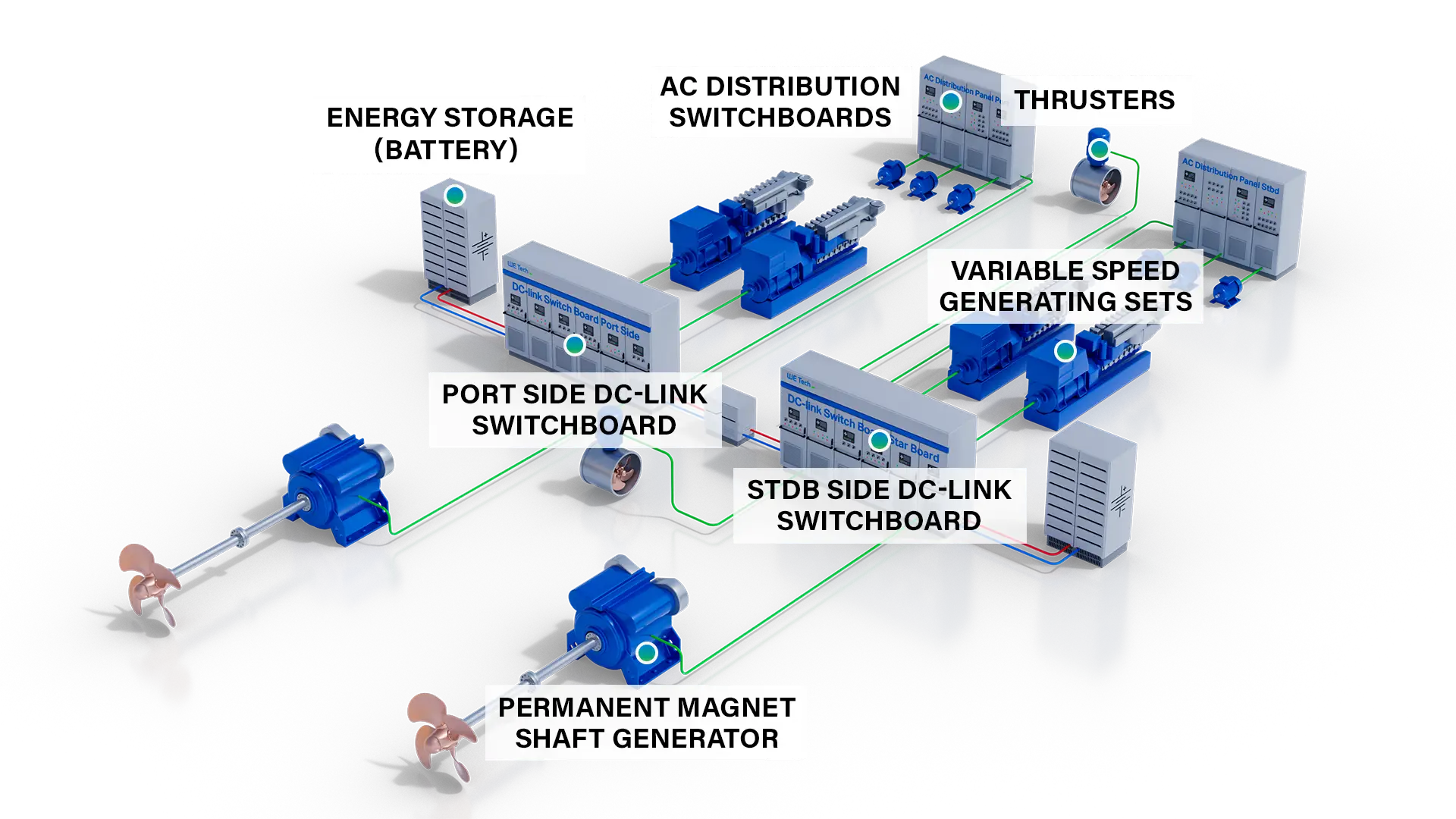

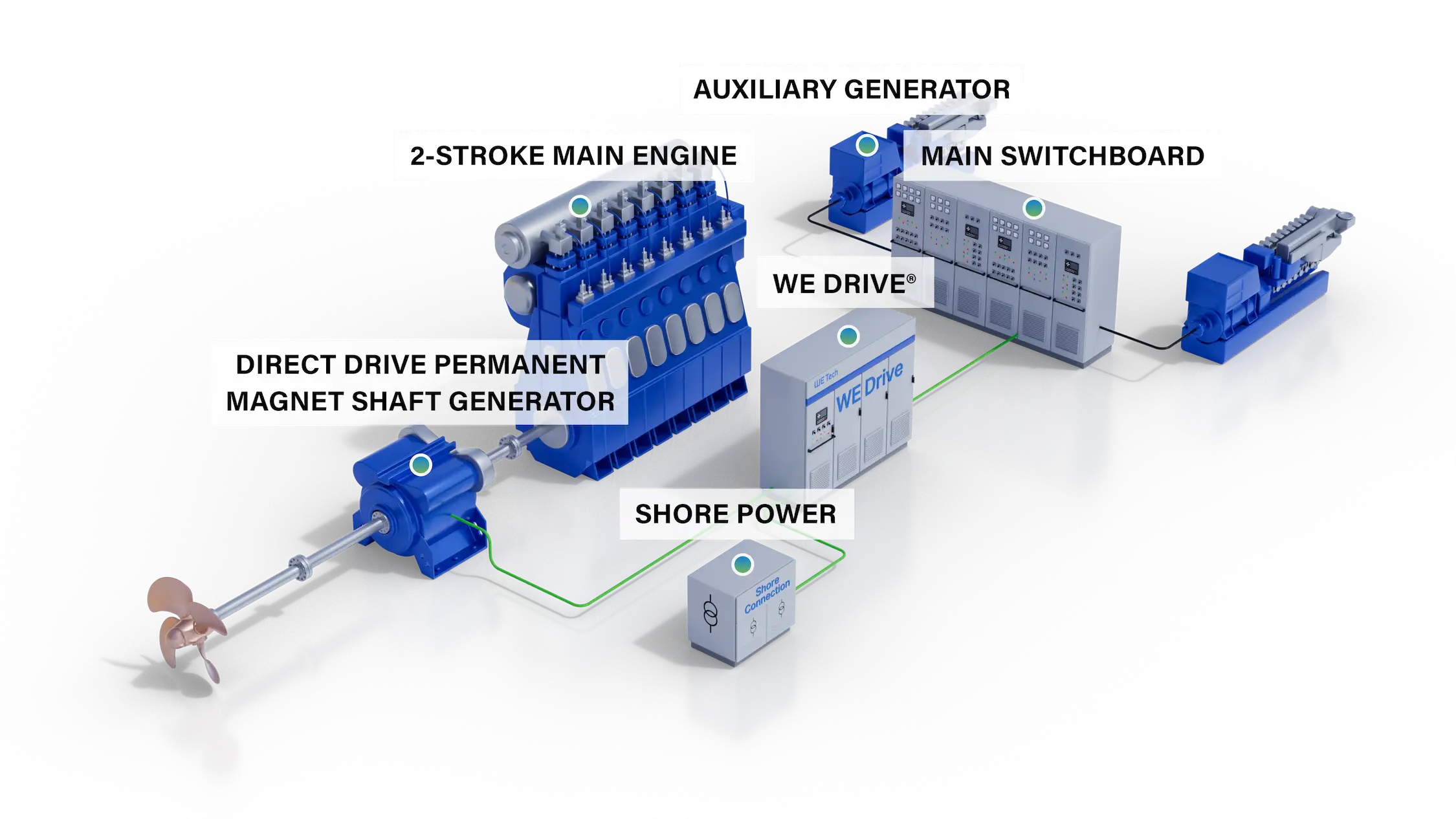

Solution Four

DC-Link Power Distribution

Efficient Energy Management for Marine Systems

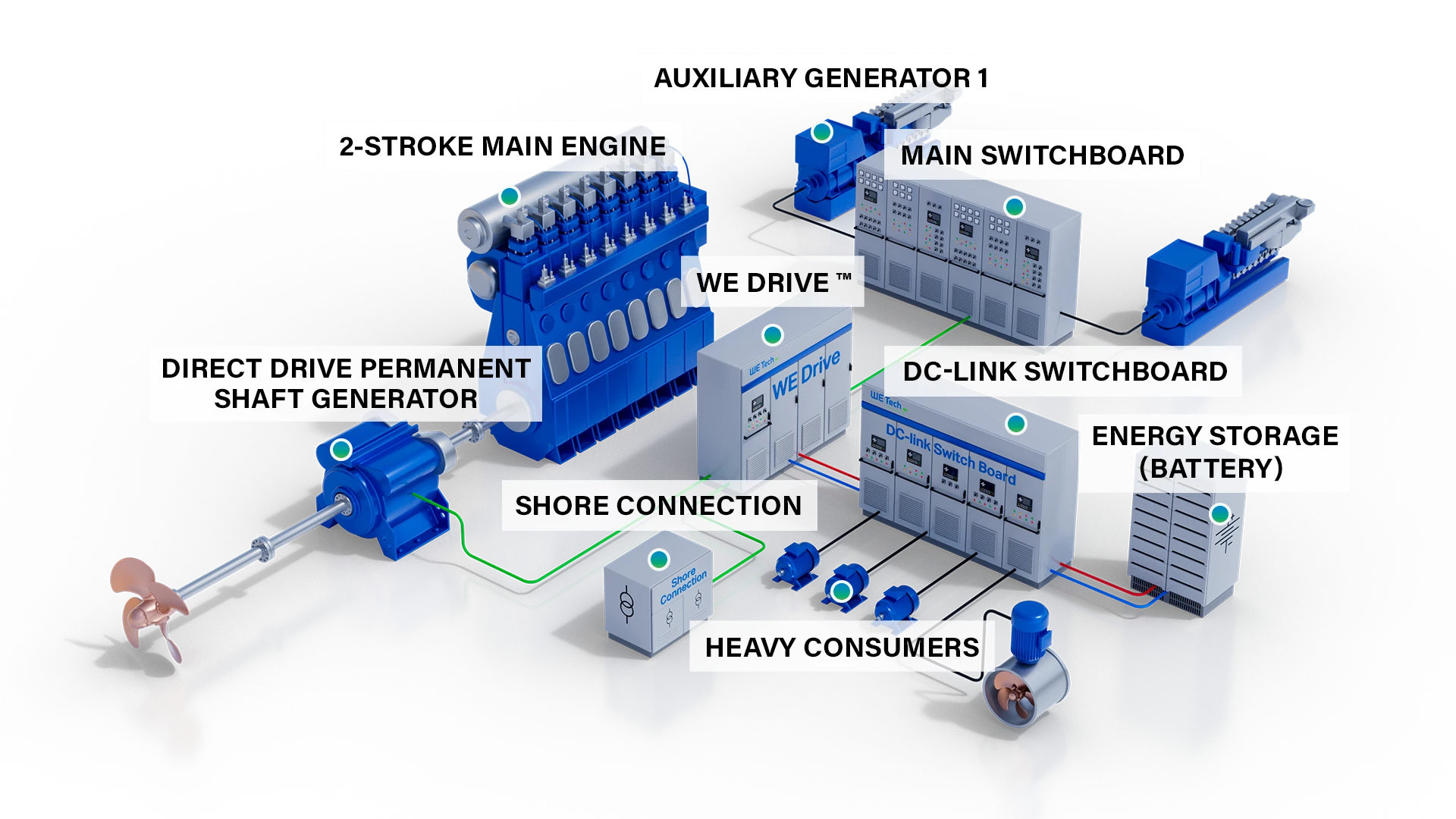

Solution two

PTI take me home

Auxiliary Propulsion for Safe Return

Solution five

Hybrid Electric Propulsion

Sustainable Marine Power Solutions

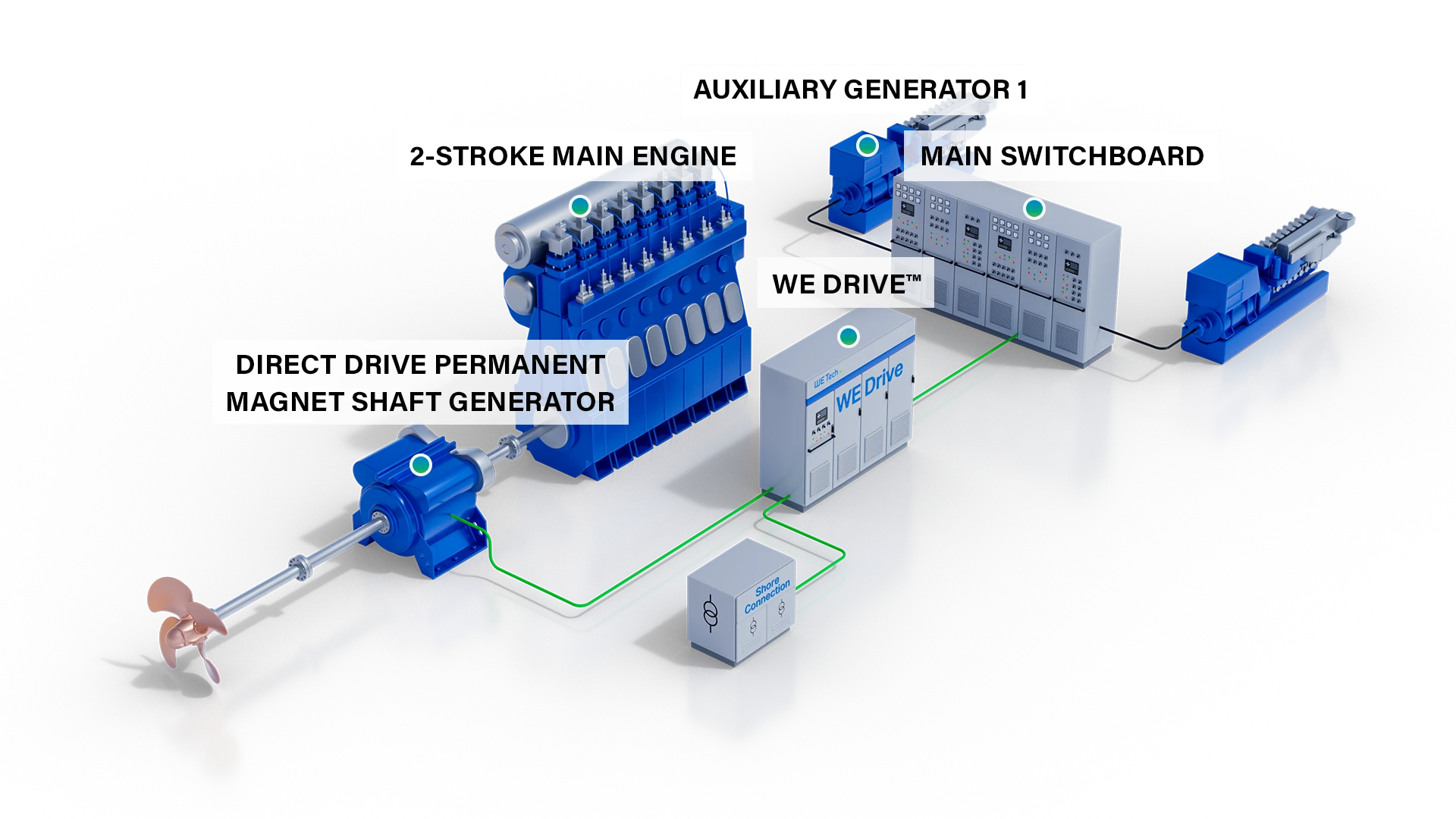

Solution three

PTI Boost Mode

Enhanced Engine Performance for Demanding Conditions

Upgrade projects

Retrofits

Adding an in-line shaft generator on the propeller shaftline

- Ship types

- Technologies

- References

- Benefits

- Services