Frontpage > Ship types > ROPAX

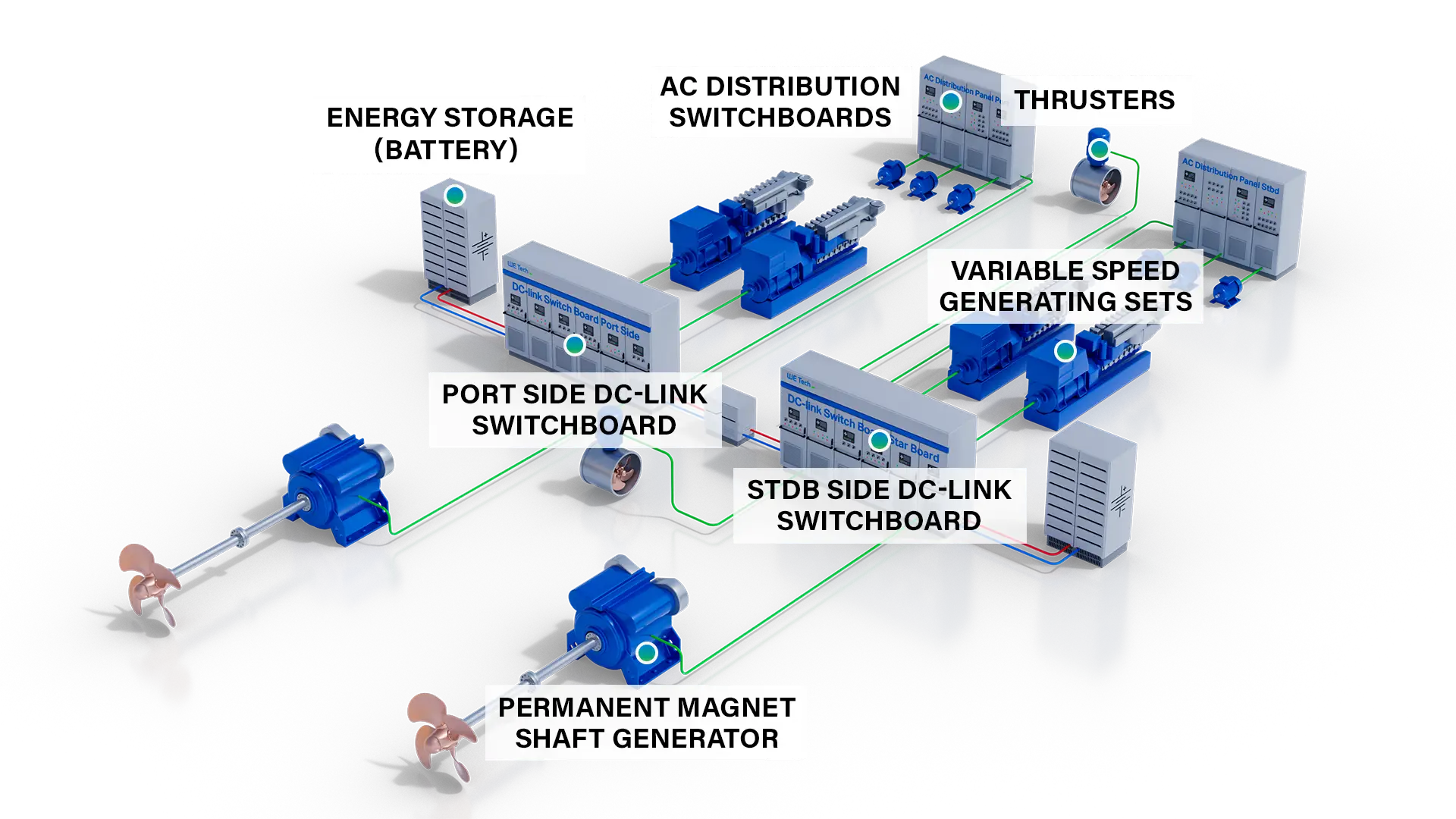

WE Tech Solution Four is the most common solution used for ROPAX. Solution Four uses the common DC-link of the WE Drive technology, thereby enabling new methods of distributing power in energy-efficient and economical ways.

The shaft generator solution also improves the Energy Efficiency Design Index (EEDI) for the vessel as it can be used as a booster for the main engine. Using the shaft generator for boosting the main engine to reach the maximum speed of the vessel allows much higher flexibility on main engine selection and thus further improving the energy efficiency of the vessel.

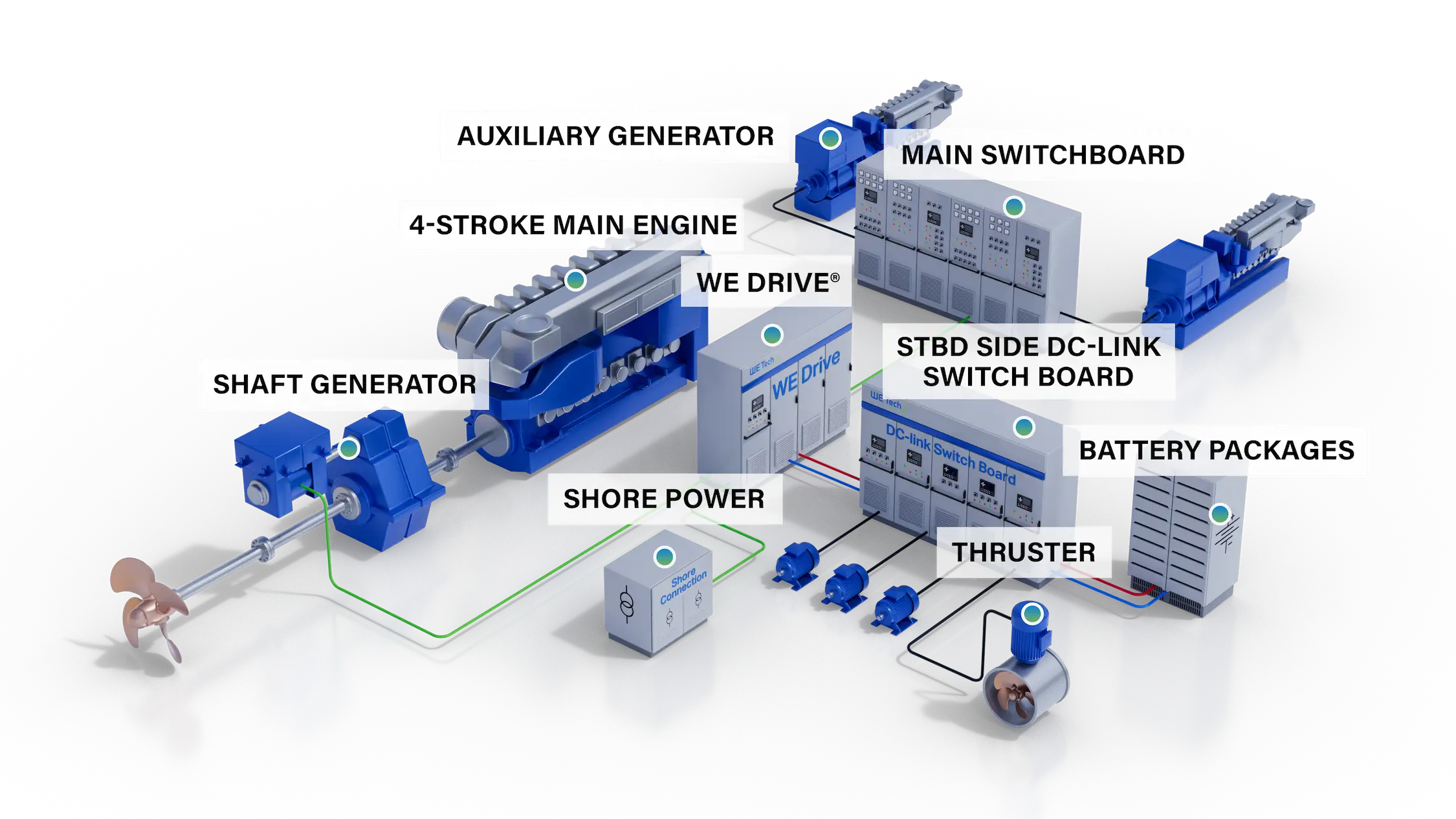

DC Power from the frequency drives for the shaft generator can be distributed to inverter units for powering the tunnel thrusters. The use of frequency inverter units over normal AC frequency converters will greatly reduce THD on main switchboard.

WE Tech Solutions, is a company specialised in developing energy solutions for ships and the market leader for permanent magnet shaft generator solutions. The company has long experience in developing the most energy efficiency solution for any ship type.

Taking advantage of the already existing variable frequency drives the vessel can allow shore frequencies of both 50Hz and 60Hz to be connected to the vessel. This will further enhance the environmental footprint when auxiliary engines can remain shut off during cargo operations in port.

Peak-shaving

The Peak-shaving mode can be used for supporting auxiliary engines by taking on fast load changes and keeping electrical load as seen for auxiliary engines constant.

Spinning reserve

Spinning reserve functionality provides an energy reserve for power generation, allowing for single generator operation.

Black-out prevention

In case a generator is unexpectedly shut down, the ESS keeps the electrical network energized until a Stand-by Auxiliary Generator comes on-line.

Electric Propulsion

The ESS can feed power to shaft generators / motors to provide electric propulsion for the vessel. In this mode neither main engines nor auxiliary engines are running. Can be used for emission free propulsion in and out of harbour.

DC Power from the frequency drives for the shaft generator can be distributed to inverter units for powering heavy consumers, such as a bow thruster and a cargo handling system. The use of frequency inverter units over normal AC frequency converters will greatly reduce THD on main switchboard.

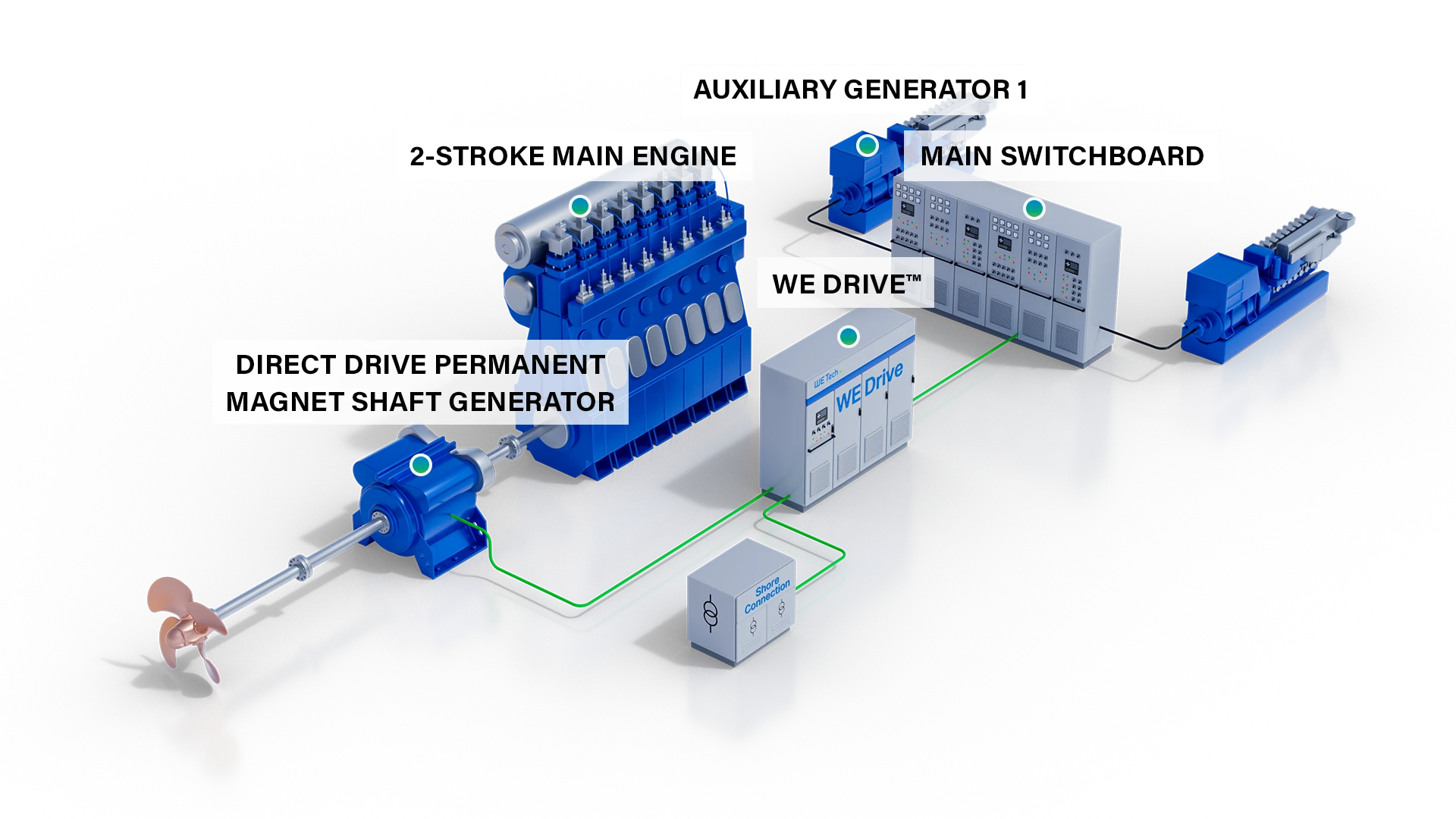

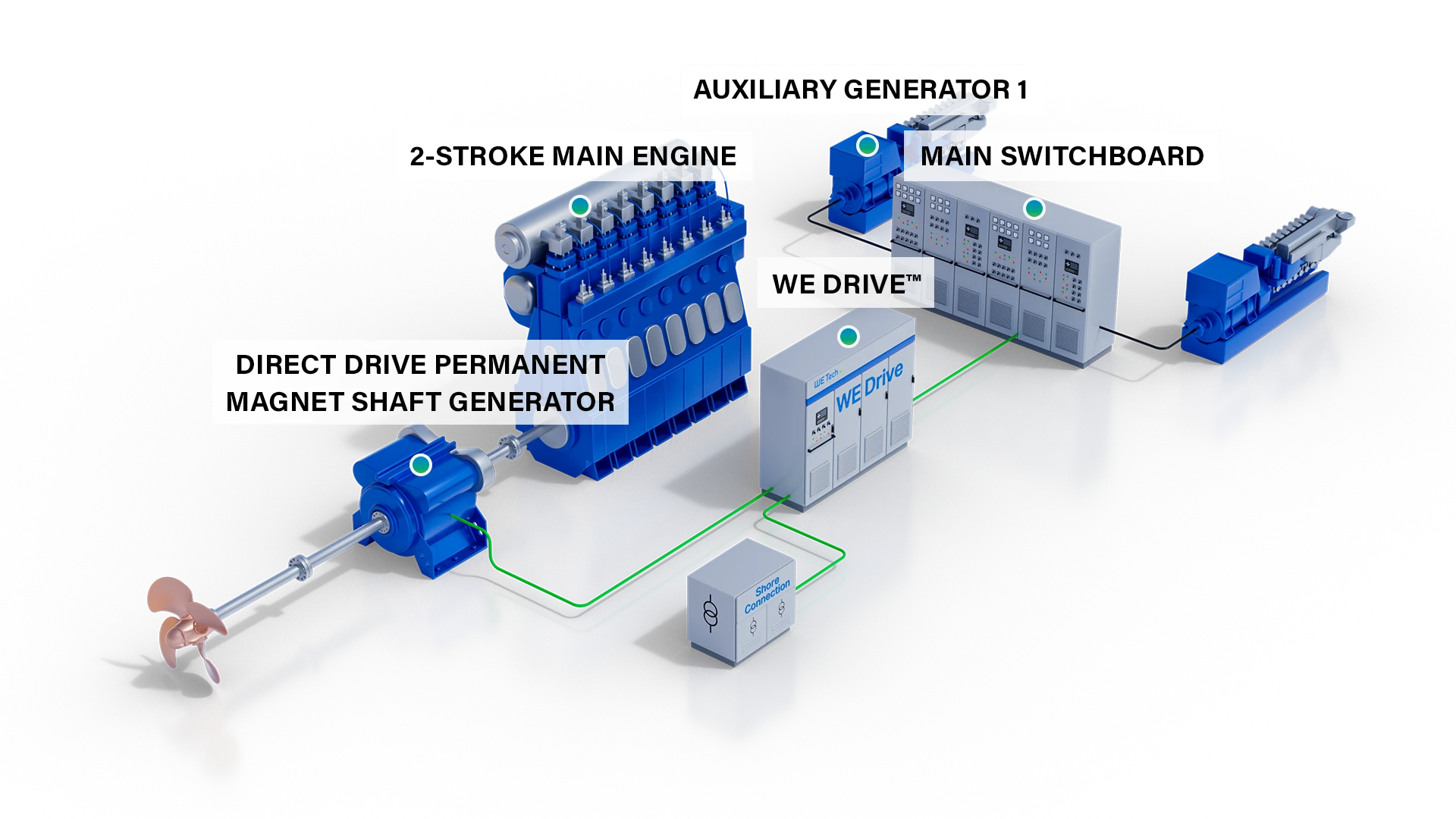

Our solutions build on widely proven technologies and are applicable for most ship types and propulsion machinery (e.g. low speed direct driven propeller with 2-stroke Main Engine, or medium speed reduction gear driven propeller with 4-stroke Main Engine).

WE Tech solutions utilise variable frequency drive technology (WE Drive™), permanent magnet generator technology, DC-link power distribution and Energy Management System(EMS).

With our domain expertise, you can get a ship with an energy system built the way it should.

Variable frequency drive technology for generator/motor applications is a compact and robust modular design.

The variable speed permanent magnet generator is lightweight, and compact-sized with the highest efficiency over the full speed and power range. It is virtually maintenance-free. We also offer solutions based on synchronous and asynchronous generator technology.

We use the latest lithium-ion technology from the Energy Storage System (ESS) suppliers. With a DC-DC converter, we integrate the ESS into our solution.

With the Energy Management System(EMS), we control various operation modes of the ship as well as start/stop sequences, etc. The EMS also interfaces with other control systems on board a ship.

Shore power is conditioned for the vessels’ electrical system via the WE Drive™. Vessels become unaffected by the variations in voltages and frequencies of the national power grids worldwide – shore power is always matching.

Fuel Cell Integration via DC/DC conversion to the ship energy efficient power distribution system. Seamless operations utilising Fuel Cells and ESS combinations for zero emission power.

We have been focusing on lowering emissions for years by providing cost-effective and sustainable lifetime solutions to the shipping industry. Our benchmarking solutions have already been applied to more than 150 vessels worldwide.

"*" indicates required fields

Vaasanpuistikko 19, 2nd floor, 65100 Vaasa, Finland

Tel.: +358 20 786 1680

Email: solutions(at)wetech.fi

VAT No.: FI22885604

Contact us today to tailor a solution for your vessel.