Frontpage > Ship types > Gas Carriers

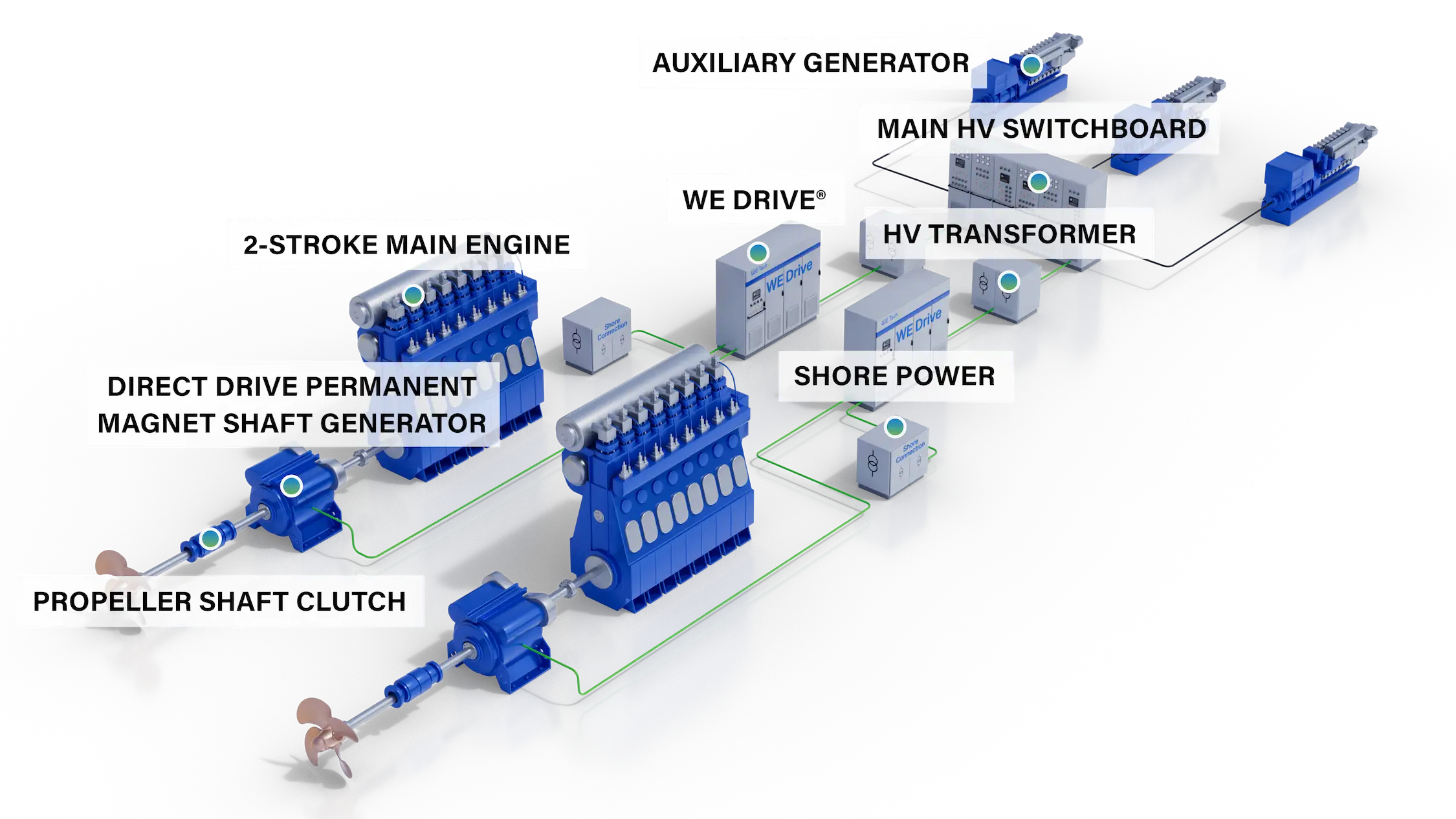

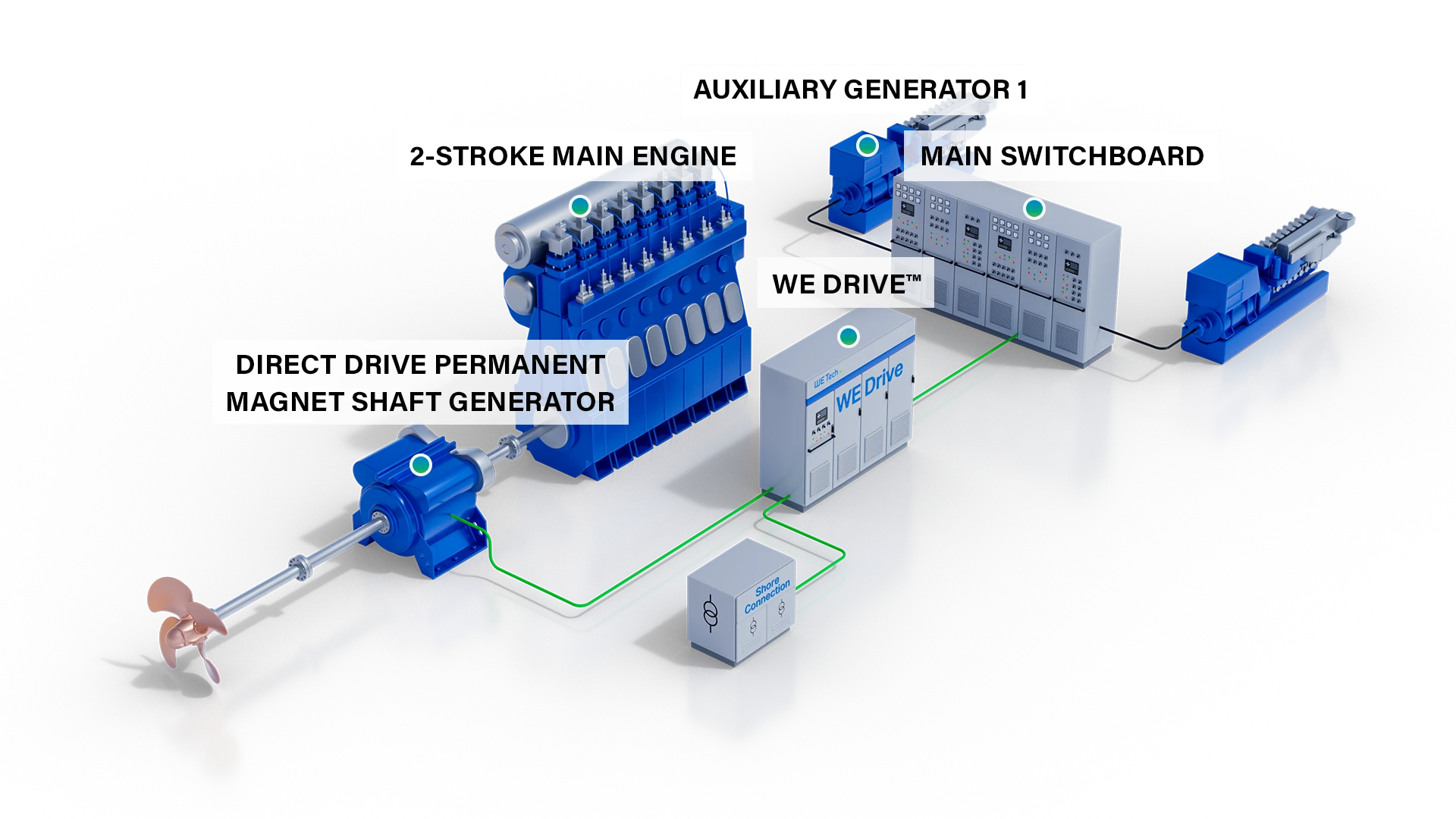

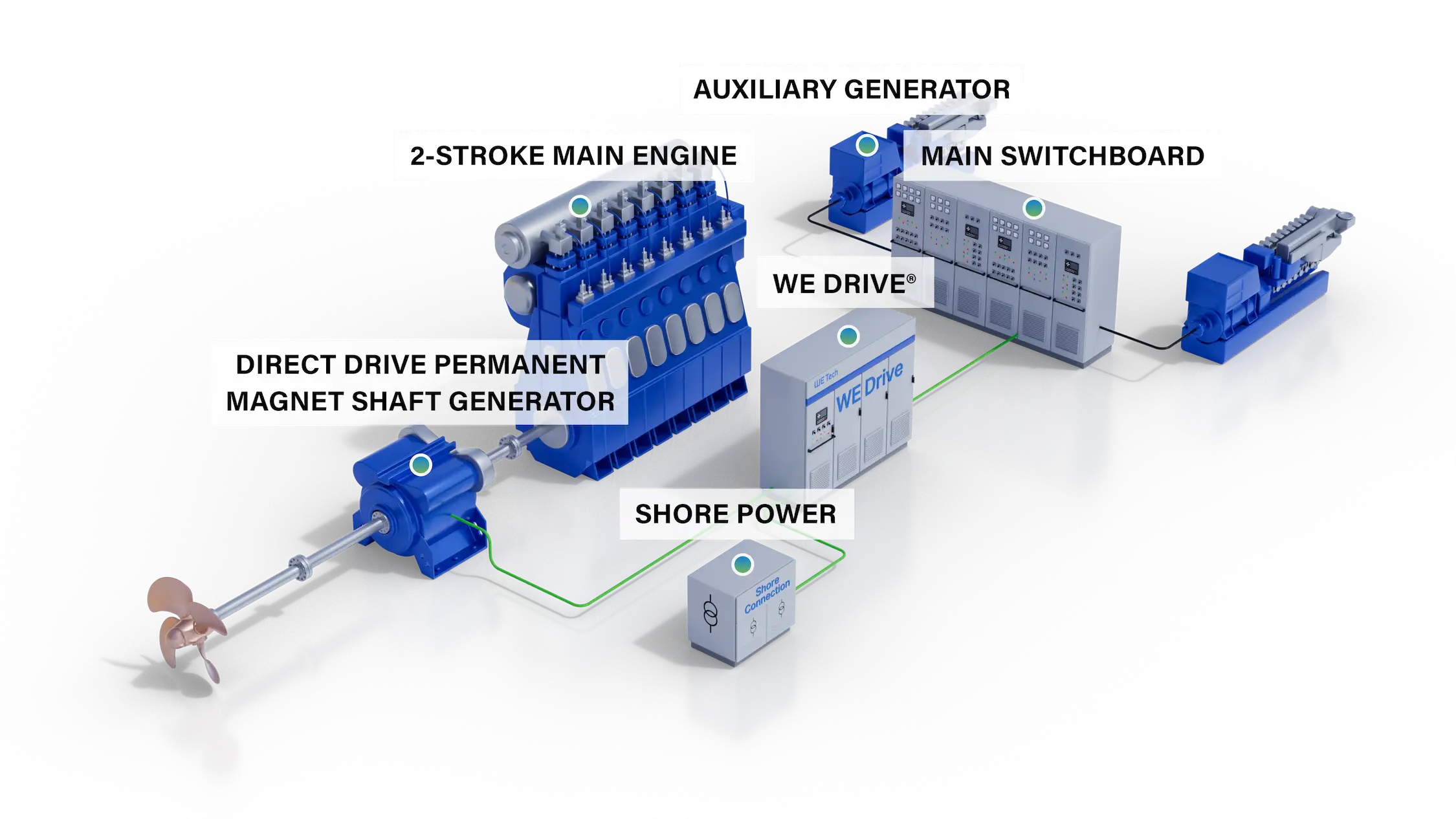

For LPG Carriers, Solution One with single shaft is most common solution used. The shaft generator becomes especially important when the main engine is running on LPG boil-off, as the main engine can produce both propulsion and electrical power for the vessel. This limits the running hours of auxiliary engines, and as a result the auxiliary engines are not burning a secondary type of fuel for producing electricity.

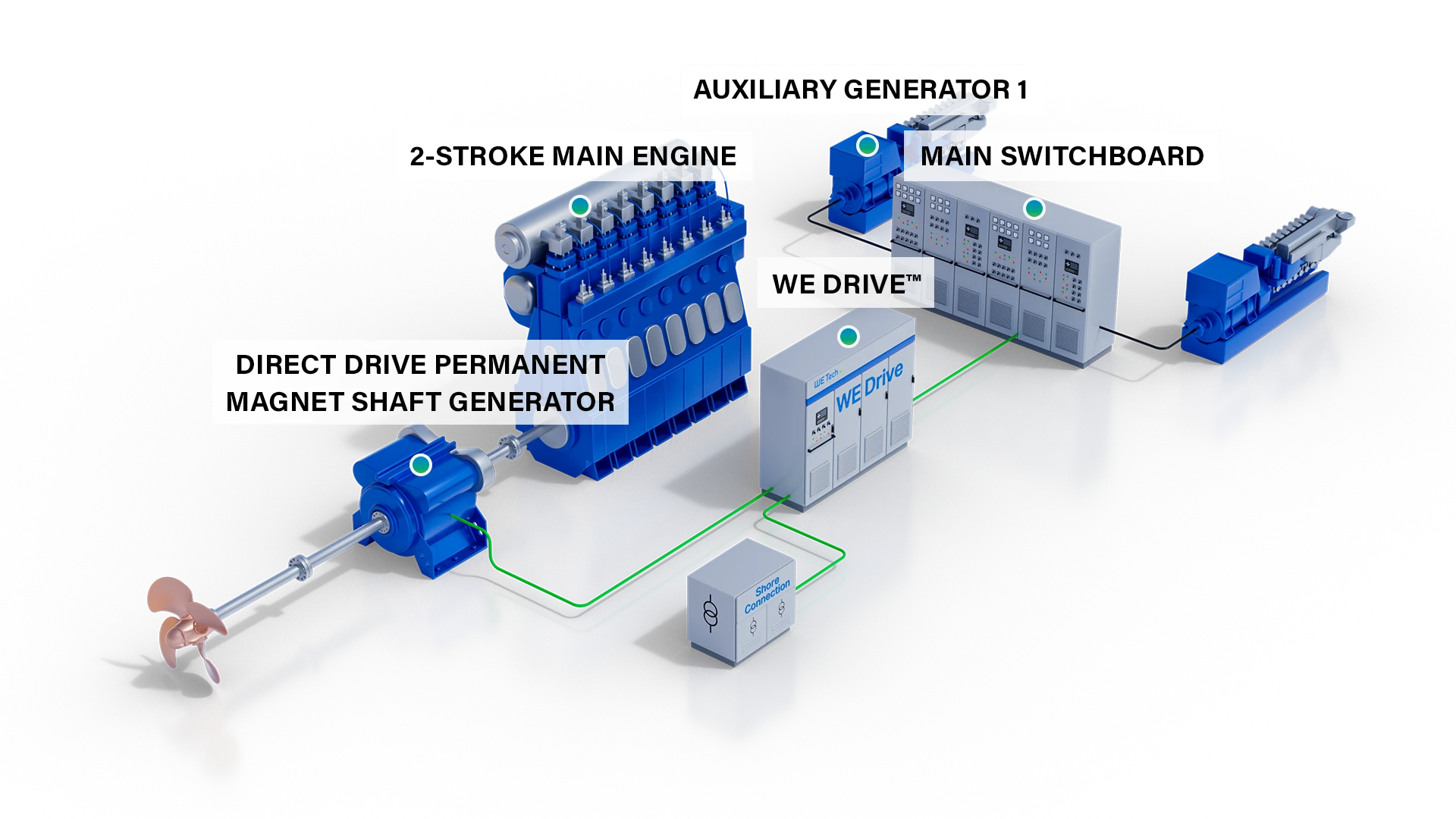

For LNG Carriers, Solution One with twin shaft is most common solution used.

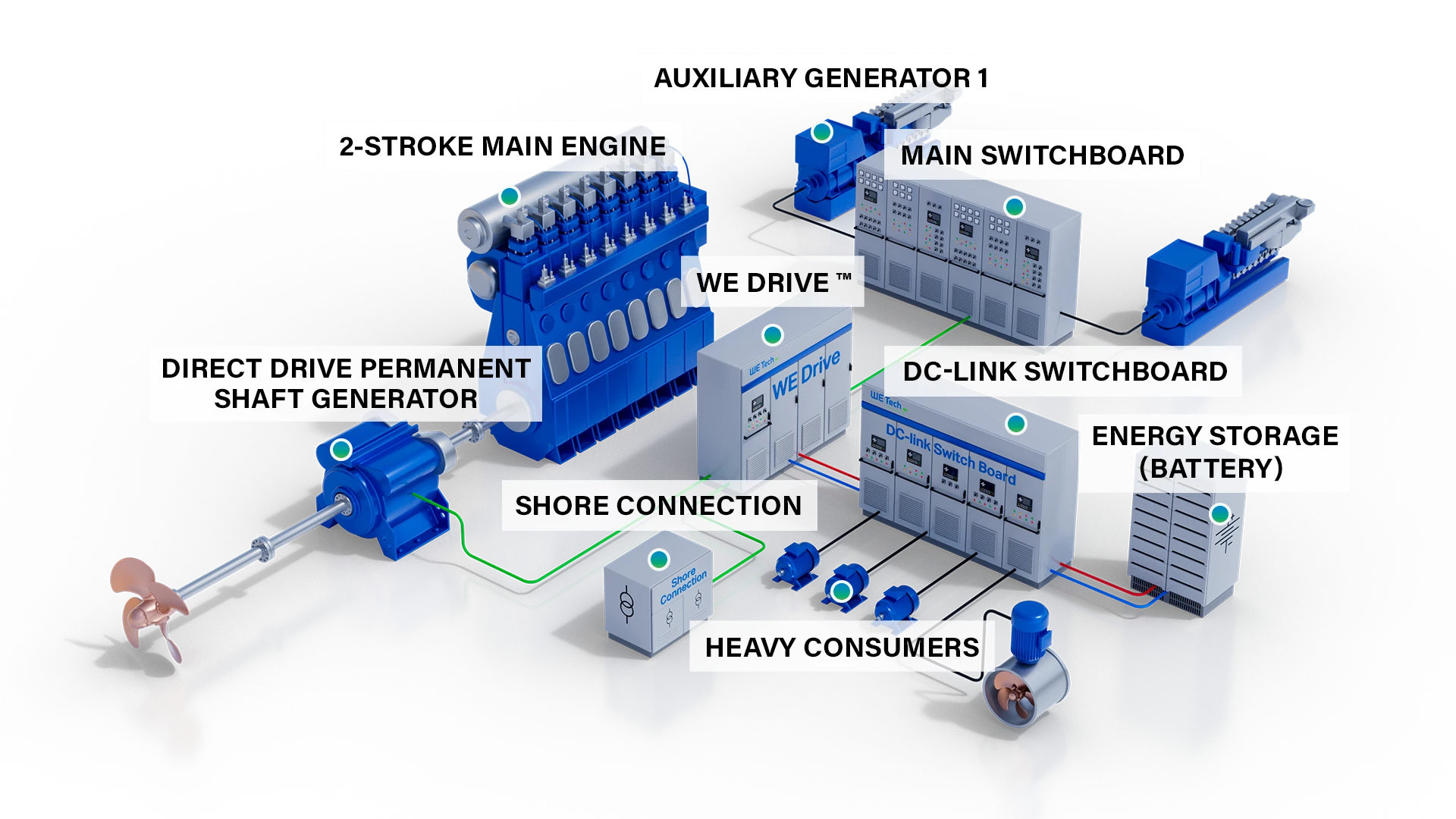

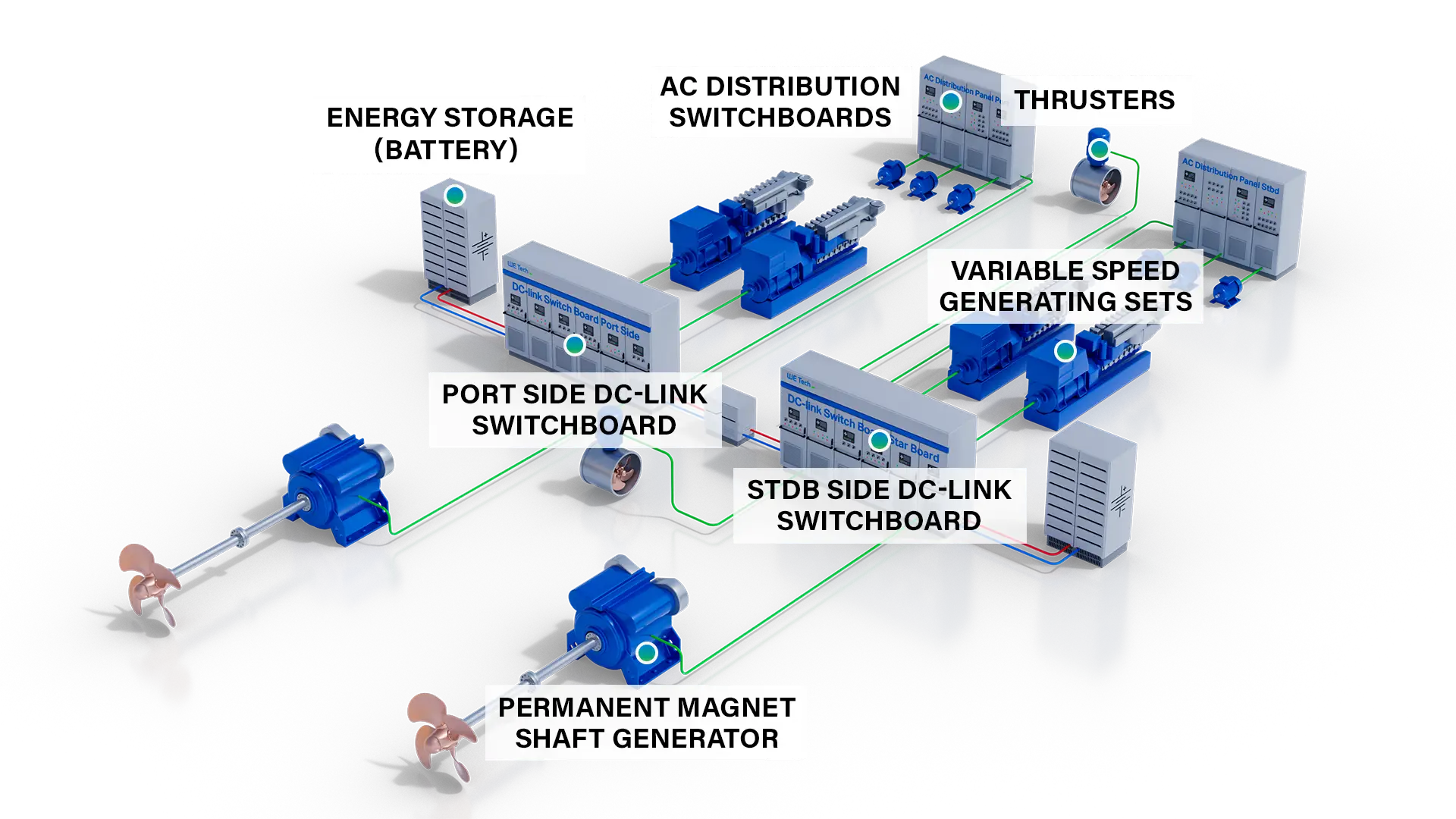

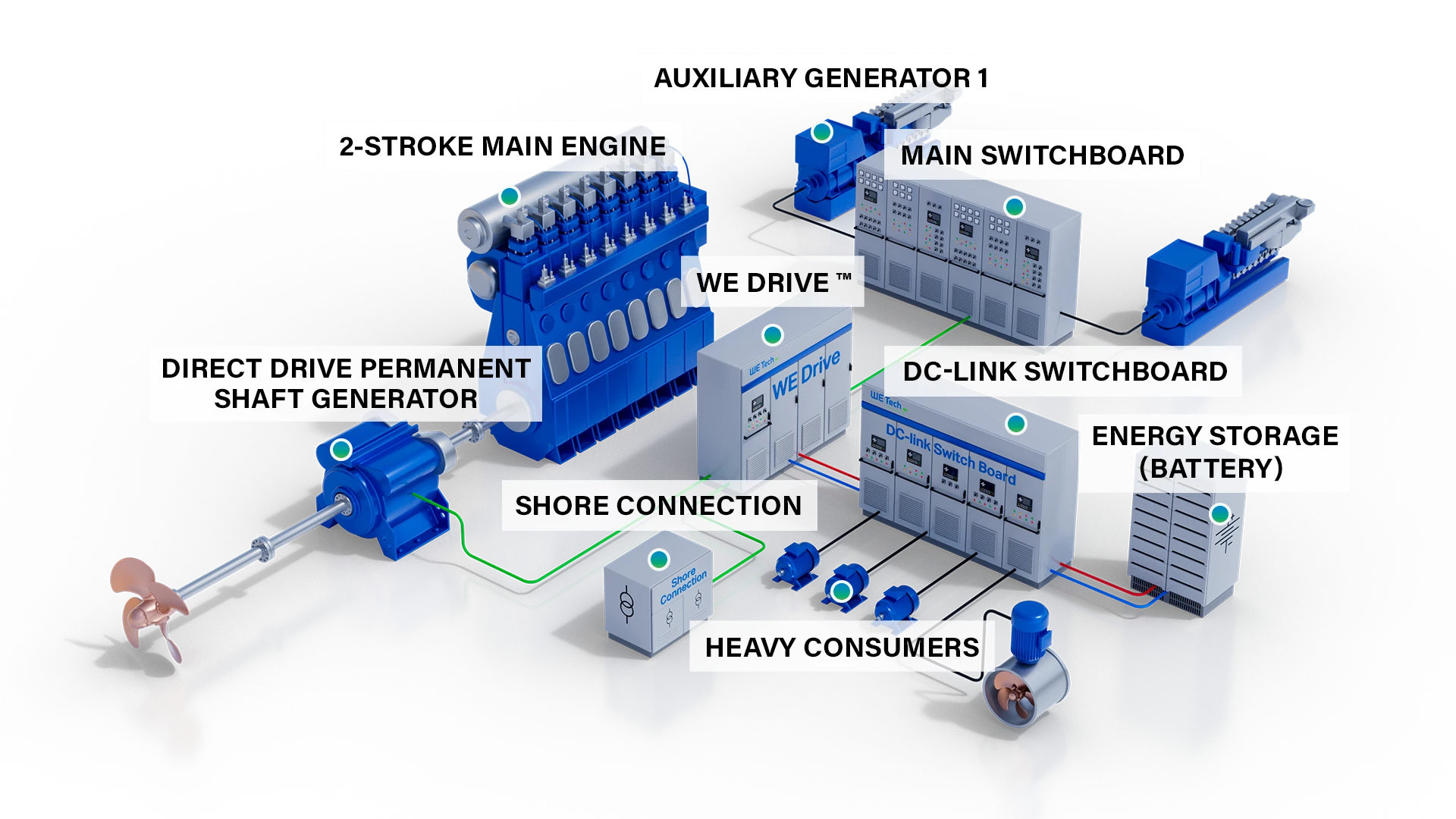

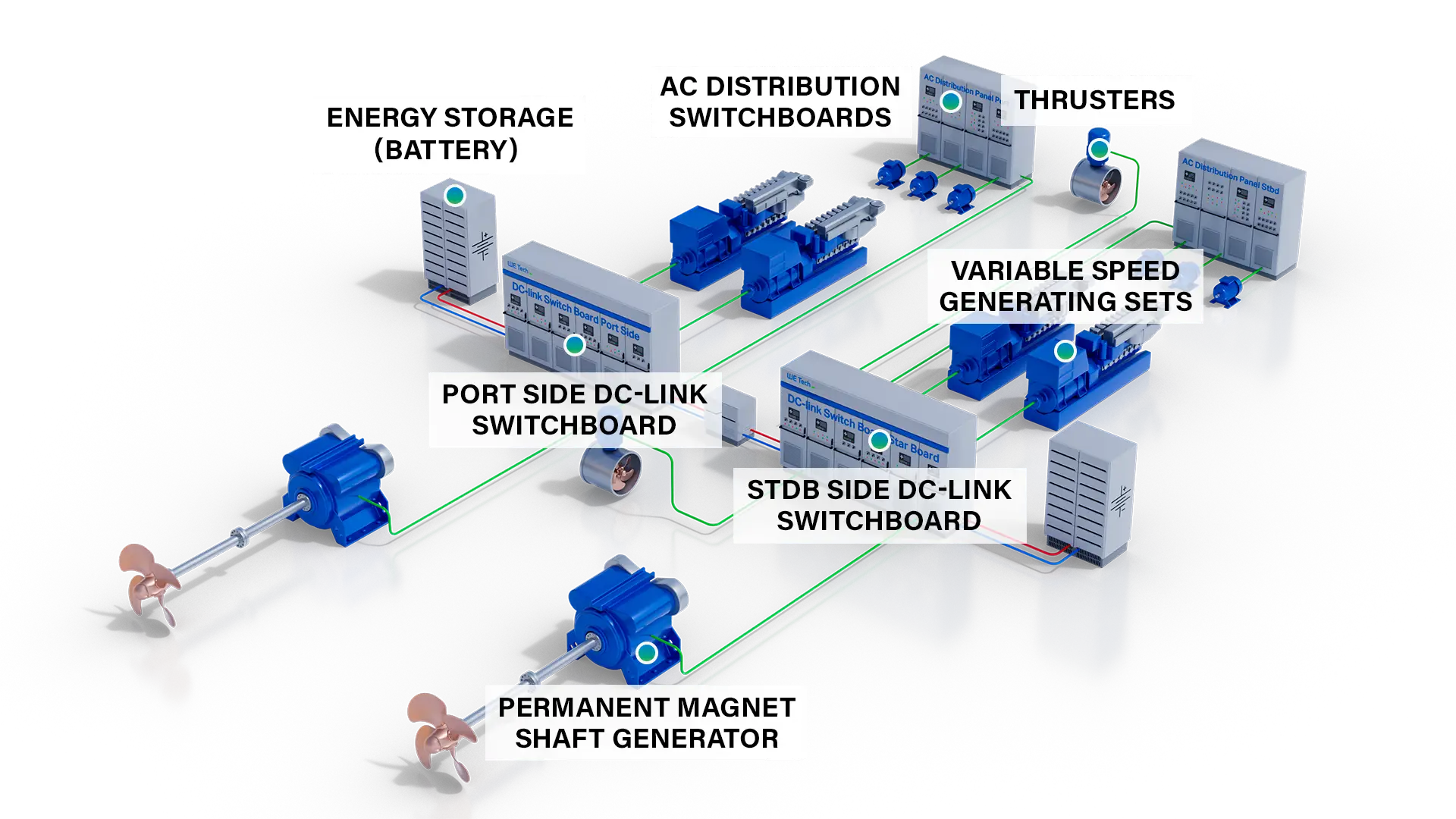

Thanks to WE Tech’s modular integration platform, Solution One can be extended with various options to further improve the energy efficiency of the vessel.

WE Tech Solutions is a company specialised in developing energy solutions for ships and the market leader for permanent magnet shaft generator solutions. The company has long experience in developing the most energy efficiency solution for any ship type.

Taking advantage of the already existing variable frequency drives the vessel can allow shore frequencies of both 50Hz and 60Hz to be connected to the vessel. This will further enhance the environmental footprint when auxiliary engines can remain shut off during cargo operations in port.

As an option the shaft generator can have two separate windings, each winding feeding the main switchboard via its own frequency drives. This will eliminate a blackout in case of a failure in any of the two feeders as the other remain intact.

Taking advantage of the already existing variable frequency drives the vessel can allow shore frequencies of both 50Hz and 60Hz to be connected to the vessel. This will further enhance the environmental footprint when auxiliary engines can remain shut off during cargo operations in port.

As an option the shaft generator can have two separate windings, each winding feeding the main switchboard via its own frequency drives. This will eliminate a blackout in case of a failure in any of the two feeders as the other remain intact.

Our solutions build on widely proven technologies and are applicable for most ship types and propulsion machinery (e.g. low speed direct driven propeller with 2-stroke Main Engine, or medium speed reduction gear driven propeller with 4-stroke Main Engine).

WE Tech solutions utilise variable frequency drive technology (WE Drive®), permanent magnet generator technology, DC-link power distribution and Energy Management System(EMS).

With our domain expertise, you can get a ship with an energy system built the way it should.

Variable frequency drive technology for generator/motor applications is a compact and robust modular design.

The variable speed permanent magnet generator is lightweight, and compact-sized with the highest efficiency over the full speed and power range. It is virtually maintenance-free. We also offer solutions based on synchronous and asynchronous generator technology.

We use the latest lithium-ion technology from the Energy Storage System (ESS) suppliers. With a DC-DC converter, we integrate the ESS into our solution.

With the Energy Management System(EMS), we control various operation modes of the ship as well as start/stop sequences, etc. The EMS also interfaces with other control systems on board a ship.

Shore power is conditioned for the vessels’ electrical system via the WE Drive®. Vessels become unaffected by the variations in voltages and frequencies of the national power grids worldwide – shore power is always matching.

Fuel Cell Integration via DC/DC conversion to the ship energy efficient power distribution system. Seamless operations utilising Fuel Cells and ESS combinations for zero emission power.

We have been focusing on lowering emissions for years by providing cost-effective and sustainable lifetime solutions to the shipping industry. Our benchmarking solutions have already been applied to more than 150 vessels worldwide.

"*" indicates required fields