WE Tech Solutions Oy (“WE Tech”) has the honor to deliver energy solution orders consisting of a variable speed shaft generators for eight large container..

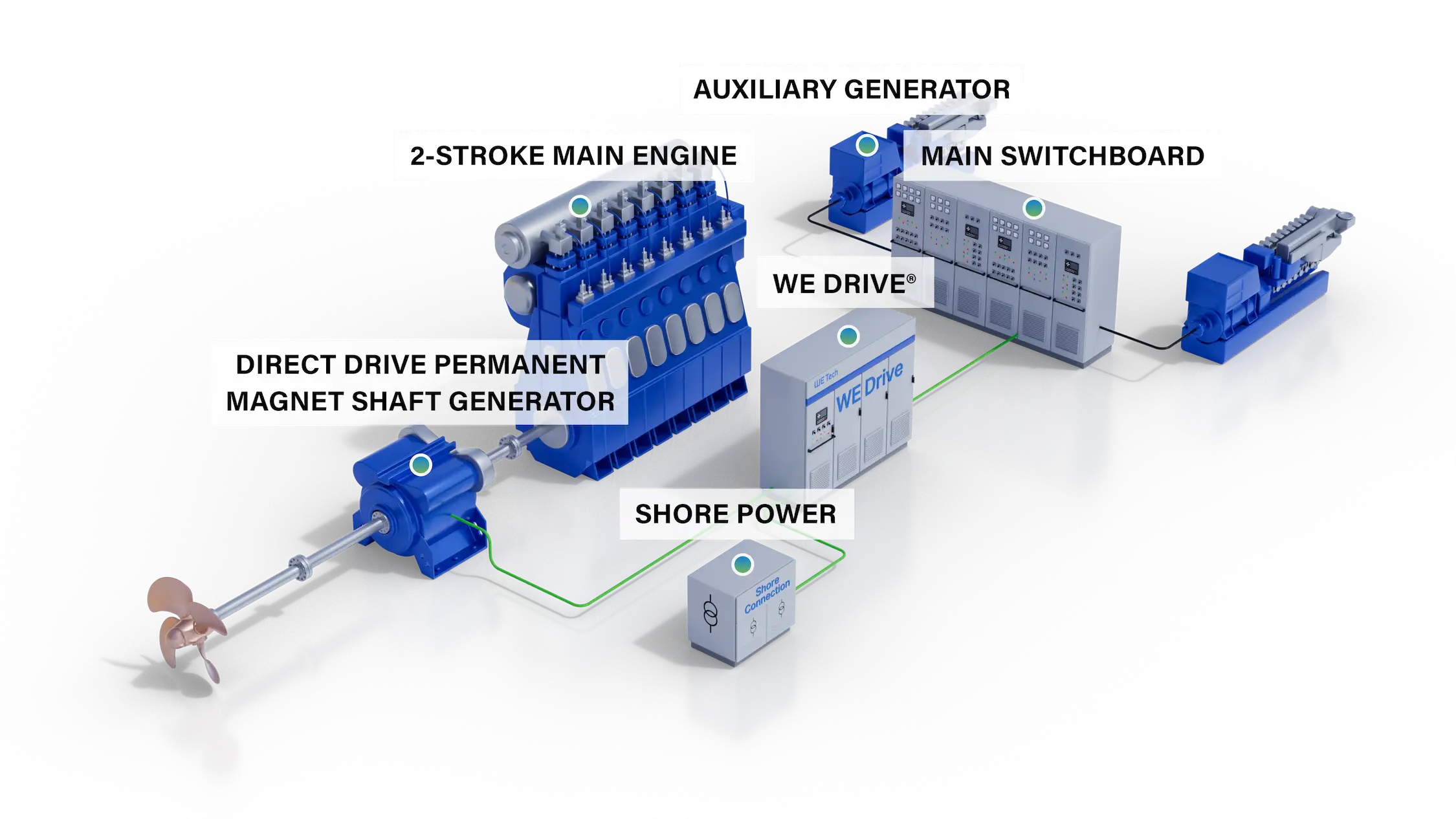

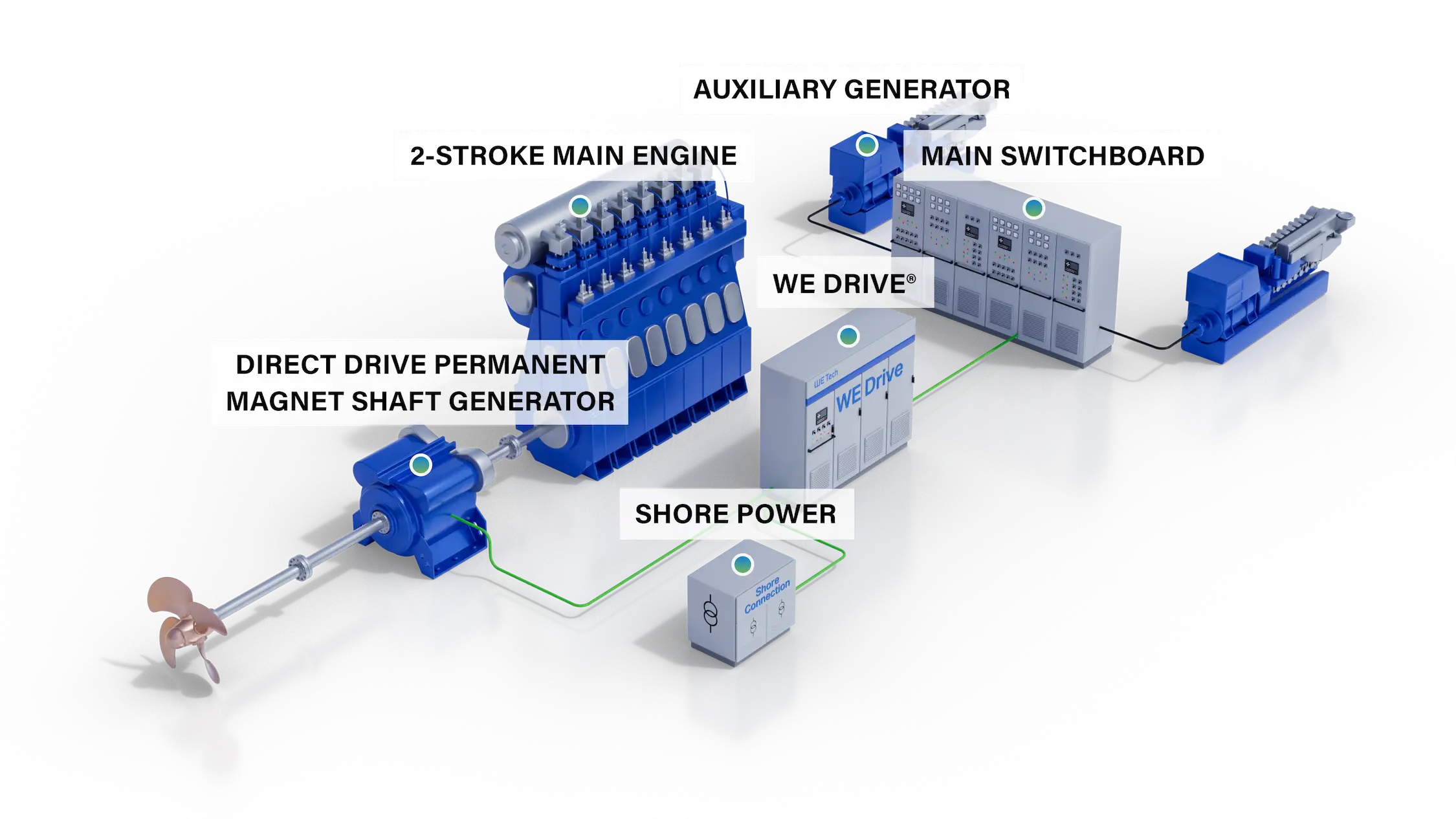

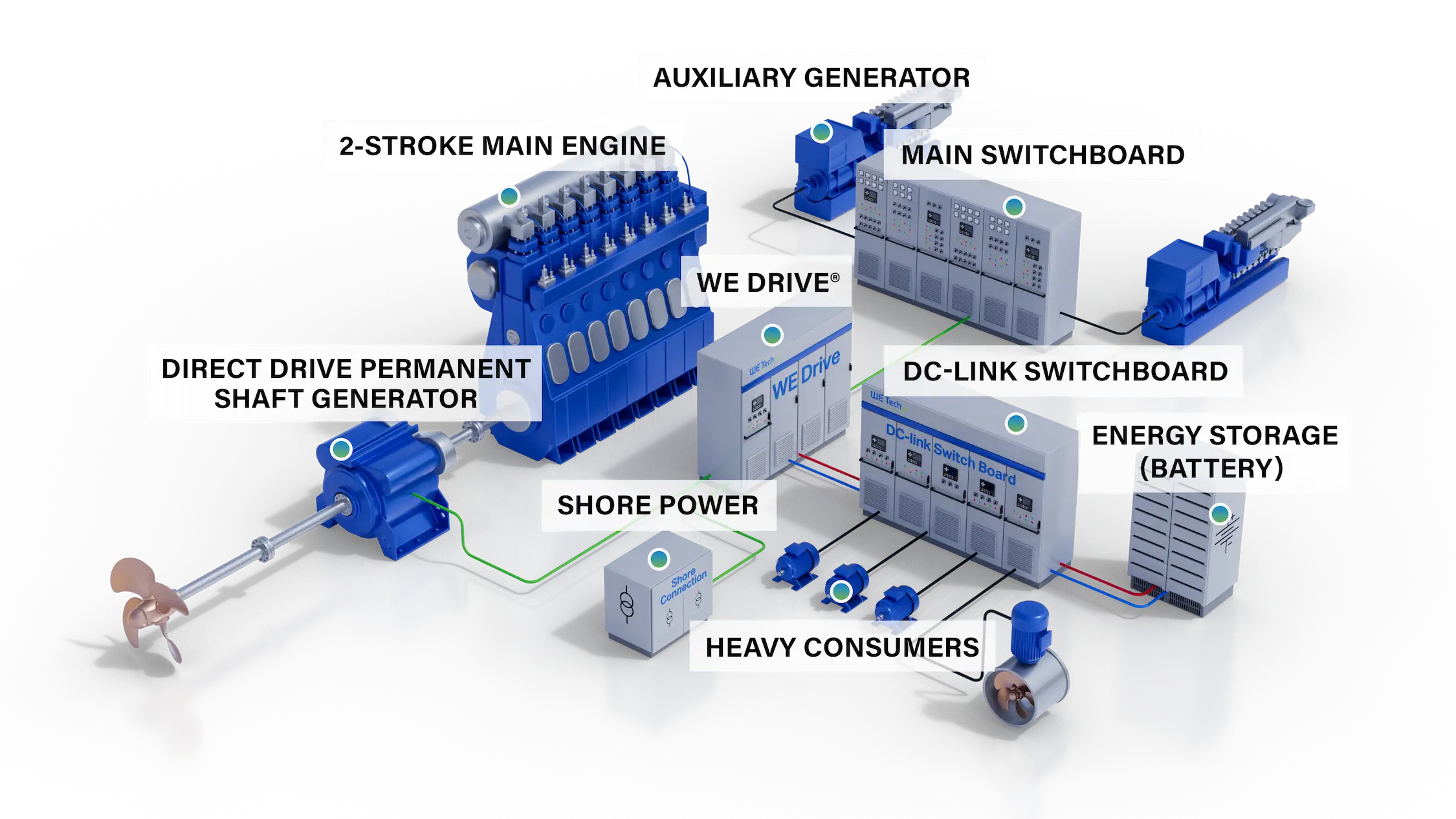

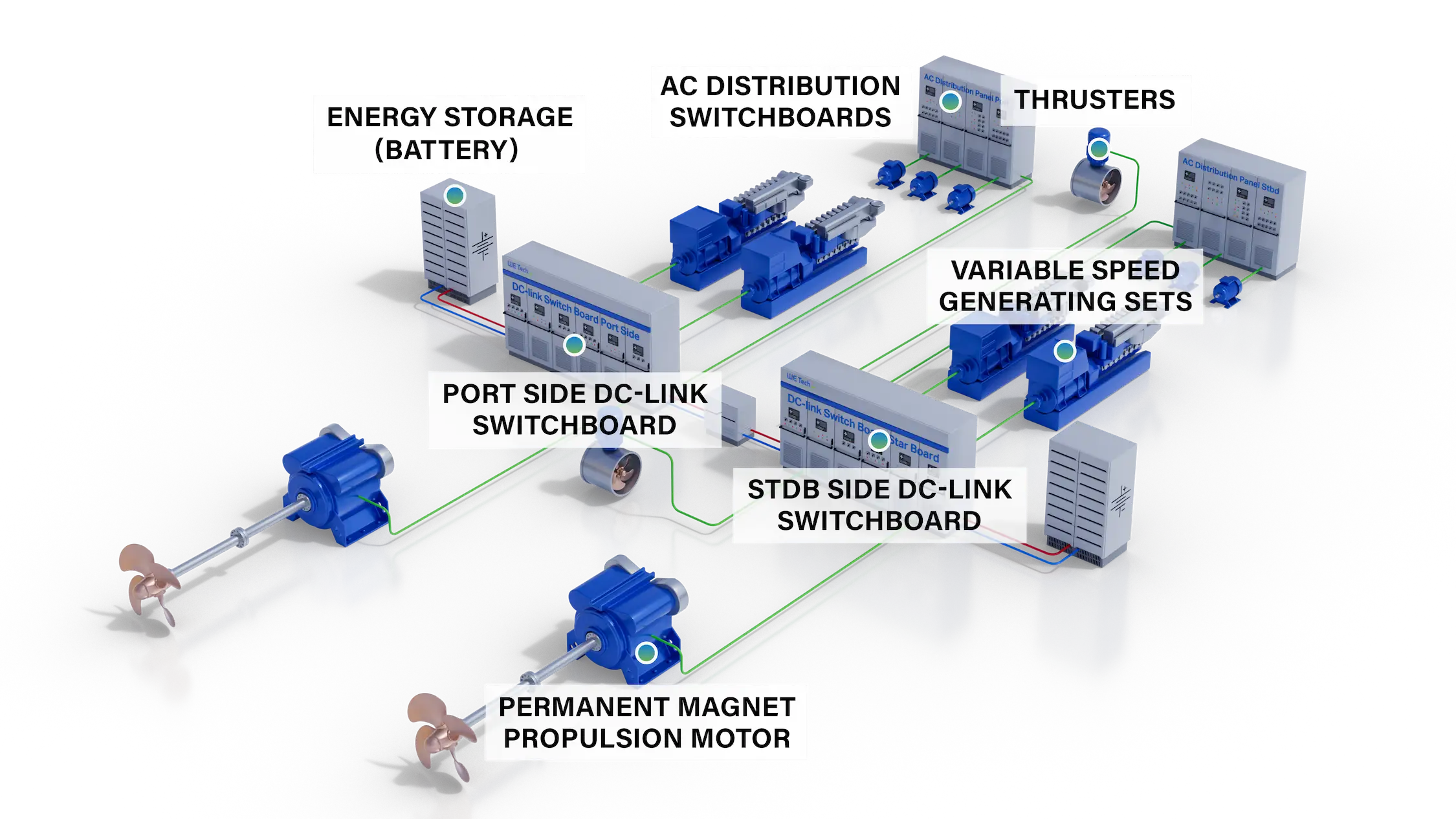

WE Tech Solutions is a leading energy solution provider with a global presence in the shipping industry. The company specialises in supplying solutions based on variable frequency drives, permanent magnet generator technology, DC-link power distribution and energy management systems.

Our solutions build on widely proven technologies and are applicable for most ship types and propulsion machinery.

We have been focusing on lowering emissions for years by providing cost-effective and sustainable lifetime solutions to the shipping industry.

Achieve substantial fuel savings and operational cost reduction from optimised propulsion machinery and reduced Auxiliary Generator operation.

Shaft Generator as a motor for Take Me Home and Auxiliary Propulsion Drive (APD).

Shaft Generator as a motor for boosting the Main Engine in demanding conditions or low load optimised Main Engine.

Efficient power distribution via the DC-link of WE Drive® to heavy consumers such as bow thrusters, pumps and compressors.

Ship wide DC-bus power distribution with variable speed shaft and auxiliary generators.

WE Tech Solutions Oy (“WE Tech”) has the honor to deliver energy solution orders consisting of a variable speed shaft generators for eight large container..

WE Tech Solutions will be exhibiting at the Hamburg Maritime Forum 2024. The forum takes place from 16th to 17th of April in Hamburg, Germany...

WE Tech Solutions will be exhibiting at Sea Japan in Tokyo 2024. The exhibition will take place from 10th of April to 12th of April...

"*" indicates required fields