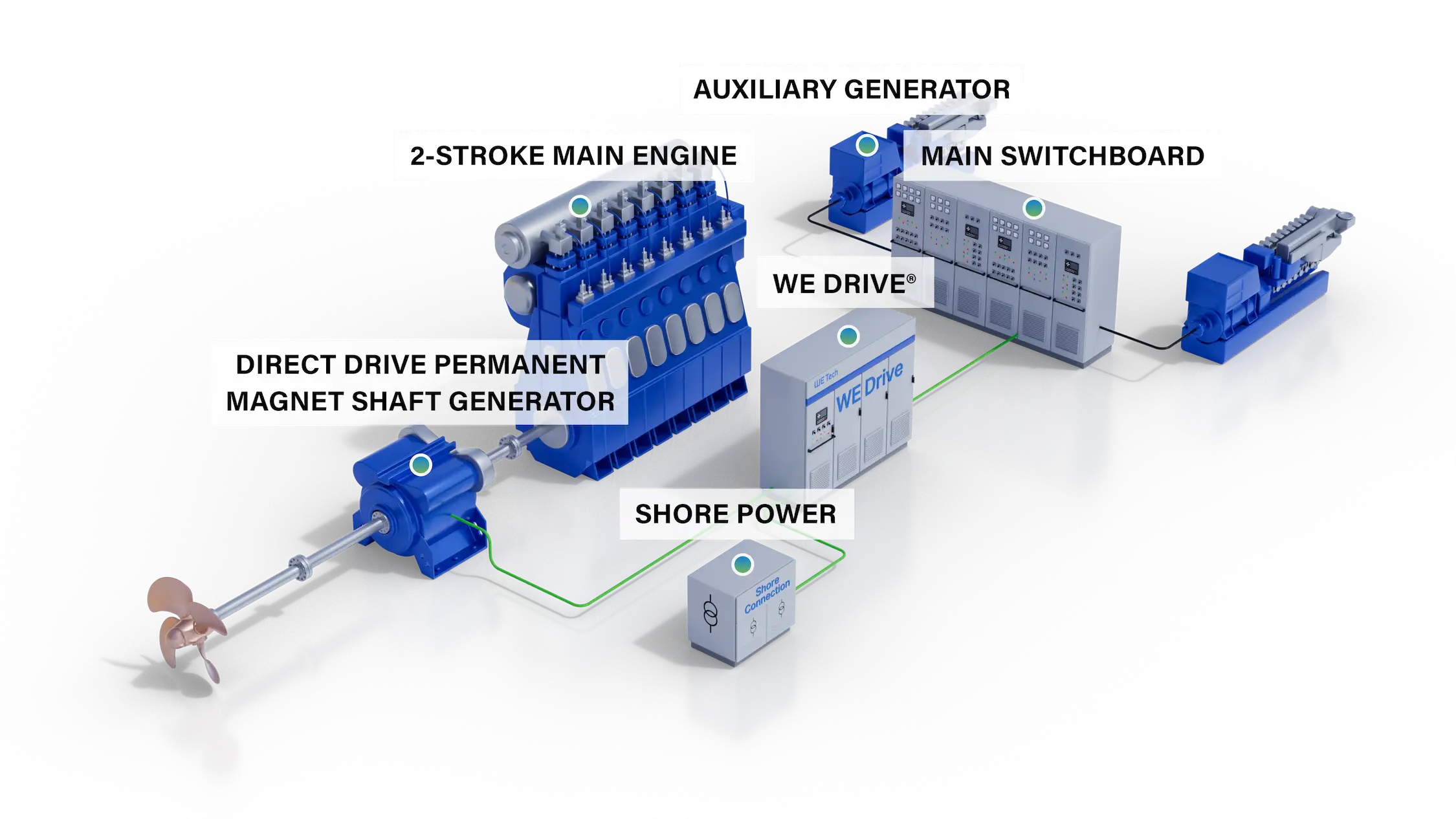

The permanent magnet rotor is mounted on the intermediate shaft of the propulsion system. Mass and inertia are very low and thus the impact on propulsion system torsional vibration calculations (TVC) remains minimal. No additional bearings are required, thus the propeller shaft system design remains uncompromised. The generator housing, consisting of a compact, feet mounted stator package, including the rotor and intermediate shaft, is positioned on the generator bed in the propeller shaft line and connected via flanges.

Solution One focuses on the energy efficient operation of any ship equipped with direct-driven propulsion machinery combined with a Shaft Generator system, also called Power Take Out (PTO) system. This solution enables the operation of propulsion machinery in combinator mode – variable speed and pitch of the propeller – with the Shaft Generator online and generating power for the ship’s electrical network. This means that the propulsion machinery can be operated at optimal duty points at all vessel speeds. Energy efficiency is improved which results in substantially reduced fuel consumption and decreased environmentally harmful emissions. This solution also enables two-stroke Main Engine installations to be realized with fixed pitch propeller so that a Shaft Generator system can be installed.

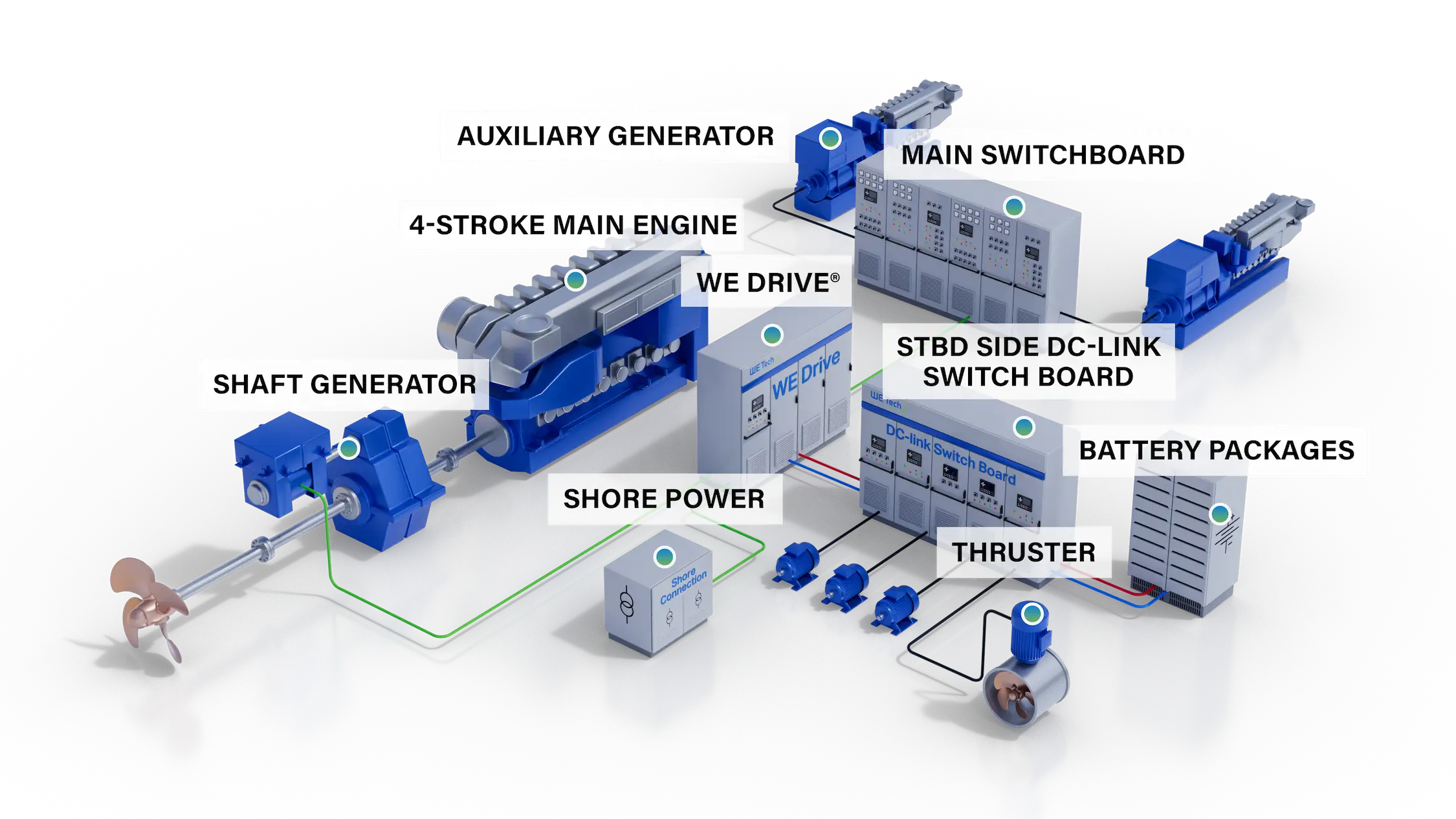

Our solutions build on widely proven technologies and are applicable for most ship types and propulsion machinery (e.g. low speed direct driven propeller with 2-stroke Main Engine, or medium speed reduction gear driven propeller with 4-stroke Main Engine).

WE Tech solutions utilise variable frequency drive technology (WE Drive®), permanent magnet generator technology, DC-link power distribution and Energy Management System(EMS).

With our domain expertise, you can get a ship with an energy system built the way it should.

Variable frequency drive technology for generator/motor applications is a compact and robust modular design.

The variable speed permanent magnet generator is lightweight, and compact-sized with the highest efficiency over the full speed and power range. It is virtually maintenance-free. We also offer solutions based on synchronous and asynchronous generator technology.

We use the latest lithium-ion technology from the Energy Storage System (ESS) suppliers. With a DC-DC converter, we integrate the ESS into our solution.

With the Energy Management System(EMS), we control various operation modes of the ship as well as start/stop sequences, etc. The EMS also interfaces with other control systems on board a ship.

Shore power is conditioned for the vessels’ electrical system via the WE Drive®. Vessels become unaffected by the variations in voltages and frequencies of the national power grids worldwide – shore power is always matching.

Fuel Cell Integration via DC/DC conversion to the ship energy efficient power distribution system. Seamless operations utilising Fuel Cells and ESS combinations for zero emission power.

We have been focusing on lowering emissions for years by providing cost-effective and sustainable lifetime solutions to the shipping industry. Our benchmarking solutions have already been applied to more than 150 vessels worldwide.

"*" indicates required fields