The shipping industry has been shifting towards decarbonisation and aiming for net zero by 2050. The transition requires ships to pursue superior energy efficiency and optimised operational functionality in a reliable, safe and economical way while reducing the environmental footprint.

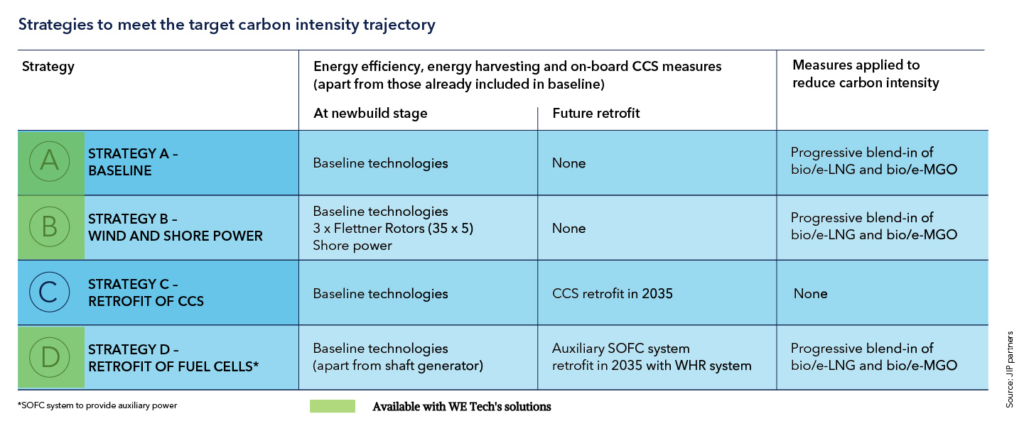

DNV’s latest study has presented several potential decarbonisation strategies (A-D) for a new LNG carrier design to determine feasible approaches to achieve compliance with the IMO decarbonisation trajectory toward 2050.

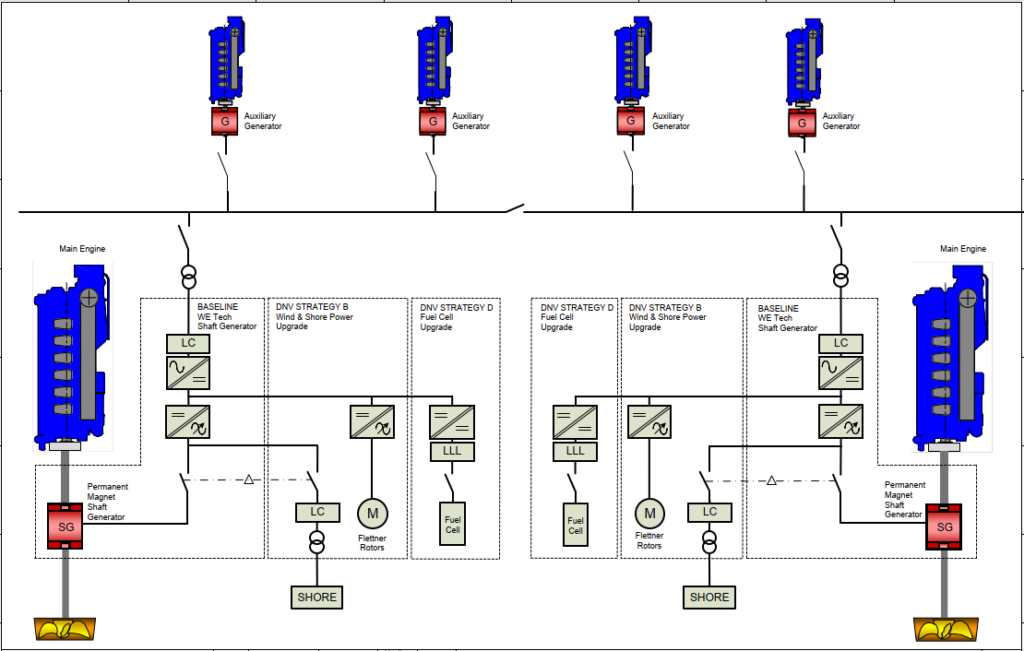

In the DNV’s vessel design study, the shaft generator solution is listed as part of the baseline solution for the vessel, providing benefits of reducing carbon footprint and enabling operational flexibility. WE Tech’s permanent magnet shaft generator with DC-link power distribution extends the possibilities of the shaft generator solution to new levels. Ship owners can expect a future-proof vessel beyond the baseline with superior energy efficiency to further reduce GHG emissions.

“It is nowadays essential to reduce GHG emissions through new technologies and low/zero carbon fuel to improve the environmental impact of vessels and to meet upcoming IMO regulations. The most effective way to achieve this target is to use permanent magnet shaft generators for power generation,” Martin Andtfolk, Sales Manager of WE Tech Solutions, “WE Tech’s permanent magnet shaft generator is compact-size with the highest efficiency over the full speed and power range. This solution has been applied to more than 100 vessels since 2010 and the market demand for it is constantly increasing. The reason behind this is that our solutions help shipowners/operators to meet the IMO regulations for the Carbon Intensity Indicator (CII) which will go into effect already in 2023.”

The potential decarbonisation strategies A–D suggested by DNV are incorporated with five additional measures to reduce carbon intensity:

Strategy A: Baseline technologies

Strategy B: Wind and Shore Power

Strategy C: Retrofit of onboard Carbon Capture and Storage (CCS)

Strategy D: Retrofit of Fuel Cells

(Picture source: DNV. Edited by WE Tech Solutions)

With WE Tech’s permanent magnet shaft generator and DC-link power distribution solutions, Strategies A, B and D can be achieved already.

(Picture: WE Tech Solutions Oy)

The DC-link power distribution enables the extension with shore power and fuel cell in a modular scaleable design to meet the energy requirements of the vessel. Instead of using auxiliary generators, the vessel can connect to shore power while in port which can reduce fuel consumption and CO2 emissions by an estimated 8-9% (relative to total annual emissions), according to DNV’s study. By utilising the fuel cells, the fuel savings are estimated to be 6-7% fuel savings and the CO2 abatement potential in the same range.

Stay tuned to our next article!

To learn more about our solutions, please visit www.wetech.fi/solutions